- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate

Whats the Best Way to Restore Clear Plastic Windows?

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Sails, Rigging & Deck Gear

Mast Steps: No Perfect Design

Part 1-among nine different steps, of three distinct types, each has its pros and cons. but when all is said and done, we see advantages to the removable fastep..

In this report, first published in 1998, we discuss various designs of mast steps for climbing, or for assisted climbing. Here is a link to this print version of the original report on mast steps, which includes the black and white images. Since this report, we’ve done a number of other reports on mast climbing. For our most recent reports use the website search tool and search under “going aloft” or “bosun’s chair” or “mast steps” or “mast climbing” and that should bring up the more recent reports. Although some of these products are no longer available and new ones have been introduced, the designs for mast steps have not changed significantly since this report.

High on the list of chores for which its difficult to find volunteers are trips to the masthead.

But aboard most boats, it sooner or later is unavoidable. A fouled or lost halyard, an expired lightbulb, a damaged antenna or wind sensor…and up you go.

Perhaps the least tremulous ride is in a well-made boatswains chair slung from a recently inspected, powerhouse halyard, on an integral masthead sheave, whose tail is tended by your two best friends, neither of whom is a beneficiary on your insurance policies.

Doing the window shade trick rarely is that idyllic. Sometimes you even have to go it alone, sometimes on something other than a flat calm morning, sometimes even underway.

Some good minds have worked on this problem. They’ve come up with steps attached to the mast; web ladders; drums that contain multi-purchase mechanisms; and mountain-climbers hand grippers and stirrups (the hand grips contain cam cleats). Well look at all of them we can find, plus a home brew block-and-tackle/chair-cleat system used by an expert rigger.

For this report, well deal only with mast steps, which probably constitute the most commonly seen mast climbing method aboard shorthanded cruising boats. In a subsequent issue, well look at the other systems mentioned above.

Nine Mast Steps In All We collected all the steps we could find-nine in all and mounted them on a short section of mast once aboard a Prout 37 catamaran that, while doing the Inland Waterway, snagged a spreader on a tree and ripped out a big chunk of mast. Paul Boyce, manager of Hood Yacht Spars, responded to our request by grabbing a saber saw and cheerily saying, About six feet, you say?

The mast steps come in three basic flavors-fixed, folding and one demountable.

The five fixed versions carry twin liabilities. Except for one very small step, they create considerable wind resistance and theres little you do about that. They also snag errant lines, such as halyards and sometimes sheets, a tendency that can be minimized (with some of them) by rigging a fine wire or light line along their outside edges, tensioned with turnbuckles. That creates even more windage, of course, and makes the mast begin to look like a truss left over from the Eiffel Tower. In our experience, even this wire, however, may have a tendency to catch lines, especially those with a soft hand.

The three folding models eliminate much of the windage and virtually all of the snag potential, but do not provide footing as secure and comfortable as most of the fixed steps.

The ninth sample? Its a permanent or demountable step that the inventor intends should be used with an attendant safety harness manipulated with a sliding cam cleat device.

All of these steps involve drilling many holes in your mast. Weve never read or been told that drilling holes in a mast removes enough material to worry about. Further, weve never heard of a mast failing because of such holes. Nevertheless, one surely likes to minimize the number of holes.

Because it is considerable work to install such steps, its not recommended that it be done when the mast is stepped. Exerting pressure on a drill bit (and applying lubricant to preserve the bit) is difficult enough to do when the mast is on sawhorses, let alone aloft. Its minor, but you also would wind up with a lot of nasty sharp aluminum curlicues on your deck.

And whether you intend to use plain aluminum rivets or stainless machine screws or 305 stainless rivets (with a threadlock or insulating paste to inhibit corrosion), tapping good, clean threads or operating a rivet gun also is difficult if youre confined to a boatswains chair.

Stainless steel machine screws are nearly twice as strong as pop rivets, but 3/16″ 5052 aluminum rivets have a shear strength of 500 pounds (1/4″ 5052 rivets go up to 850 pounds). Nobody recommends self-tapping screws for this job.

For our tests, we took the easy way and installed all the steps with aluminum rivets. (We had enough practice in drilling and tapping aluminum when we last year worked on the mast of our Tartan 44 test boat.)

To attach these steps, we used a stock rivet gun that cost about $30. If you use stainless rivets or aluminum rivets larger than 3/16″, youll need a compound-action gun thatll set you back a hundred and a half, unless you can rent or borrow one.

Aluminum rivets go for 2 to 8. Stainless rivets cost 8 to 22. Stainless machine screws are not cheap. Whatever you choose, with two or more per step, youll need quite a few to attach alternating steps the recommended 16″ to18″ apart. Measure and divide to get the steps evenly spaced. Youll want two opposing steps for standing at the top; consider carefully how far these two should be from the top of the mast.

The Stainless Triangles The most flattering thing to be said about the strap-type steps is that they sort of enclose the foot, once it is inserted, and provide a more secure feeling than the open steps.

The two stainless steps-one sold by ABI Industries, Inc. ($18), the other by West Marine ($14)-appear to be identical except for the tread material. The West version, bottom left in the photo, has a grooved teak piece. The ABI, second from the bottom left, has a black urethane instep pad.

These steps are heavy. They weigh 11-1/2 ounces.

Both have tightly spaced holes for six fasteners…too many in our opinion. If either of these steps were our choice, wed utilize but four of the holes, two at the top, two at the bottom.

The least flattering thing to be said about these steps is that a size 10-1/2 male shoe can just barely be inserted in the opening. Extracting a foot requires a bit of a bowlegged can’t.

These steps provide lateral security and are very nice hand grips. However, the difficulty of inserting and removing a foot makes them-at least for those with average to large feet-a bit clumsy and perhaps even slightly dangerous.

Further, they snag halyards and, being stainless, need careful anti-corrosion treatment to isolate the stainless from the mast.

If you favor either of these steps (we don’t), try one (mounted) for size before you commit.

Triangle & Trapezoid On the bottom right in the photo is an aluminum step shown in the Defender Industries catalog. It sells for $8.60. Our files show it used to be made by United Die and Manufacturing Co. in Sebring, Ohio, but we got a not in service message when we telephoned and Defender could not supply the name of the maker.

So, we do not know who makes it now, but most anybody could.

That’s because it is a piece of anodized aluminum tubing, bent and flattened in the proper places to form a step and for mounting holes for fasteners. (Weve never been taken with anything that utilizes flattened tubing; too many failures.)

This step has three closely spaced fastening holes at the top and three of the same ilk at the bottom and thats several holes too many, in our view. Even if using two at the top and two at the bottom, the holes are very close together.

Its simple and strong and cheap.

It weighs but 8 ounces.

It makes a fairly comfortable hand hold.

The opening for ones foot is more generous than the two discussed above. However, the narrow rounded tread is tough on the instep. If you wear thin-soled boat shoes, youll get enough in a hurry.

A minor objection: This step is very unattractive; weve seen boats with a full set and the steps stand out very noticeably.

A major objection: Windage.

Unless saving a few bucks is paramount, this is not the way to go.

The other aluminum step, which makes a trapezoid with the mast, has been made for years by Pace-Edwards.

It is a wide extrusion, ribbed on one side, grooved on the other side. The ribs are for strength and ridigity, but they also make for good footing on the 2″-wide tread. The grooves, on the surfaces facing outboard, are said to make it more radar-reflective.

Being a tradezoid, the step has ample width for even a big seaboot (see photos).

The anodized extrusion is tabbed (by punch pressing away part of the flange) at the top and bottom for fastening with four rivets. The holes are widely spaced, which we like.

The Pace-Edwards step weighs 7 ounces.

It is available with an extra, a small clip, fastened with two very small rivets, that can carry a wire to vertically connect the steps and prevent halyard fouling.

In a PS review years ago, it was observed that the wide tread makes a somewhat difficult handhold. If one has small hands, this is true.

Its also true that, along with the other triangular steps, there will be considerable windage.

However, for size, rigidity, finish and comfort, we think this is the best step of its type. West Marines catalog displays the Pace-Edwards step, priced at $26.99 a pair.

The Seabird, aka Nicro aka Ronstan The Ronstan, known in an earlier life as a Seabird Mast Step then as a Nicro product, is derived from a step used aboard Bernard Moitessiers Joshua. It is described in the famous French sailors book, The Long Way .

A one-piece cast stainless half circle with an integral supporting strut, the Ronstan probably is one of the strongest steps made. It can be bent to shape. Attached with but three widely spaced fasteners, it also is, by far, the lightest at 3 ounces.

It also has, by far, the least wind resistance.

It doesn’t snag halyards. (Its also used by some sailors at the base of the mast to stand on while flaking the mainsail and dealing with the cover on boats with high booms.)

The West catalog shows it for $16.99, only $1.04 more than it cost almost 10 years ago, when we last evaluated mast steps.

So why isn’t it the perfect mast step?

Maybe it is, if you’re intrepid and have small feet.

Besides being a very poor handhold, its principal liability is that it projects from the mast less than 2″. Because the average shoe is about 4″ wide, you get support for about half of your arch or even less if you elect to place the ball of your foot on the step.

To compensate somewhat, the Ronstan step has cast into its step surface six fairly sharp teeth. Theyre intended to grip the bottom of rubber-soled boat shoes; it also means you wouldnt go up the mast barefooted.

We wouldn’t consider for an instant going up the mast with these steps unless we were wearing a harness or chair on either a tended halyard or, if singlehanded, one with a sliding cam cleat we will be discussing in a moment.

The Folding Steps The two folding steps, both made of cast aluminum, may appear in the photo to be identical. Theyre the two on the top right. In one of the photos, theyre shown in the stowed position.

Each is made up of two aluminum castings.

One casting is a movable step with a tread about 4-1/2″ long with non-skid gooves and a prominent hook on the outer edge for lateral security.

The other casting, to be mounted on the mast with four fasteners (aluminum rivets would be our choice), is shaped to permit the step to be folded up when not needed and slid down to lock in place.

As one ascends the mast, the steps are popped up and open. Those who own and use this type of step probably only forget once or twice to fold and stow each and every step while descending.

They make good, long, wide footholds; as handholds, both serve better than any others. They don’t foul halyards. Windage? About medium. Theyre a bit heavy, about 10 ounces.

The Mast Walker, made by Damage Control, is smoothly made of Almag 35. Theres evidence of careful shaping, fitting, grinding and polishing. It operates easily and has a nylon button insert, threaded for adjustment, to bear against the mast and preclude rattling.

There are six versions of the Mast Walker to fit different mast curvatures. Priced at $14.50, the Mast Walker would be especially attractive for anyone looking for a good snug fit.

The ABI folding step, well polished and anodized, also has the important nylon insert that engages the mast when the step is folded. (The ABI step used to have a black rubber button, but somebody must have decided that the adjustable nylon button was worth copying.) With either make of step, the button should be adjusted before mounting, if possible. Youll see why, on the first one you mount.

The ABI step is sold by West Marine for $15.99.

There seems to us to be little to choose between these two well-made folding steps whose principal advantages are that they reduce windage, avoid snagging lines and eliminate corrosion (if mounted with aluminum rivets).

Another folding step, also made by ABI and sold in several catalogs for $14, is more commonly used as a transom step. However, ABI feels this heavy (15-ounce) chromed brass assembly can be used on a mast. In the photos, it is the second from the top left. It folds and is held firmly by a stainless spring. It does not, however, fold quite flush enough to the mast to preclude it from snagging a 1/2″ halyard. That and its weight, plus the mish-mash of metals, make it a choice wed avoid.

A Demountable Step In the photos, half way up the left side of the mast, is another mans approach to mast steps.

Looking for a better way or the best of all worlds, Alfred Gilbert fashioned his Fastep from two pieces of 1/4″ stainless rod. Bent properly and assembled with four simple welds, the Fastep is, for an open step, very strong and quite secure.

More importantly, Fasteps can be mounted when needed and demounted coming down. No windage, no fouling, no fasteners.

Fasteps can, of course, be left in place, in which case there would be a little windage and the threat of a fouled halyard. If you mount and demount them as needed, there is, of course, the risk of dropping one.

A Fastep requires only two holes in the mast. Gilbert admits the holes are a bit fussy but he supplies stick-on templates, instructions to keep the holes perpendicular to a fore and aft line (not to the curvature of the mast) and suggests a center punch and a bradpoint bit to get clean 9/32″ holes.

Going up the mast with a canvas bucket of Fasteps, the steps are inserted in the two holes and pulled down 90 to seat them snugly in place. They have small nylon-tubing fenders to make them fit snugly and not vibrate. Coming down, a step is rotated upward 90 and pulled free of the two holes.

Gilbert strongly recommends that his Fasteps ($12.95 each) be used with what he calls a Saf-Brak. The Saf-Brak is a 12″ web strap with a cam cleat device on one end and, on the other, a locking carabiner to attach to a good harness or soft boatswains chair. The cam cleat assembly, from an Idaho mountaineering gear manufacturer, seems, by marine standards, a bit clap trappy but its certainly rugged. Rigged on a taut, stowed halyard, the Saf-Brak rides up easily as one climbs up the mast, but belays securely with a down load. One would lift the strap momentarily and slide it down a bit when coming down the mast one step at a time.

The Saf-Brak, which sells for $68.95, is a sort of store-bought Prusik knot but better, because Prusik knots can jam and require two hands to work loose. (The Prusik knot, really a hitch, was invented during World War I by an Austrian professor of music, Dr. Karl Prusik, as a way to join the broken strings of musical instruments. There are several versions, one of which, made of tape or webbing, is what is called a Chinese finger. Mountain-climbing experts using two Prusik slings, both led through a ring on a harness to foot stirrups, have climbed 100′ in about one minute.)

With the Fastep system, a mast ascent will take a bit longer than with permanent steps. And, in addition to your bag of tools for whatever job it is youre about to perform, youll have a second bag of steps to contend with. In a controlled situation this doesn’t worry us, but if going up the mast underway, the extra time and fuss could be a liability.

The Bottom Line There are here probably more than the usual personal preferences to be sorted out. Included are cost, comfort, safety, windage, esthetics, whether you fear halyard fouling and how many holes it takes to make you uneasy about your mast.

For those who want permanently installed steps and care little about windage or esthetics, the Pace-Edwards trapezoid is a good choice.

If you want an open folding step that creates less windage and is a bit more sightly, choose either the Mast Walker or the ABIs nearly identical folding aluminum step.

If very little windage and no fear of fouling is your wont, consider the small, strong Ronstan…but only if youre willing to be faithful about using a harness attached to something that will catch you if you slip.

Best overall? Unless theres something weve missed, a canvas bag of Fasteps, used in conjunction with the Saf Brak, makes sense. They can be left in place, which we wouldnt do. No fasteners and only two holes per step. Mounted only when needed, thered be no corrosion fears, nothing to foul halyards, nothing unsightly.

And if youre going up alone with any of these steps, wed recommend the use of the Saf Brak.

Contacts- ABI, 1160A Industrial Ave., Petaluma, CA 94952, 707/765-6200. Defender Industries, 42 Great Neck Road, Waterford, CT 06385, 800/628-8225. Fastep & Saf Brak, Alfred Gilbert Enterprises, 2921 Wood Pipe Lane, Phila., PA 19129, 215/849-4016. Mast Walker, Damage Control, 7670 Bay St., Pasadena, MD 21122-3433, 410/360-2445. Pace-Edwards, 2400 Commercial Blvd., Centralia, WA 98531, 800/338-3697. Ronstan, 7600 Bryan Dairy Rd., Largo, FL 33777, 813/545-1911. West Marine, 500 Westridge Dr., Watsonville, CA 95076, 800/262-8464.

RELATED ARTICLES MORE FROM AUTHOR

You can safely climb a mast halyard without a special mechanism. Prusik knots are used by mountain climbers to vertically ascent a rope without special hardware.

Very informative, but how can I see the photos ? Thanks

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Cabo Rico 34 Boat Review

Super Shallow Draft Sailboat: The Leeboard Sharpie

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boating Giveaway

How To Install Mast Steps

- By Don Street

- Updated: March 15, 2018

With the almost universal use of GPS and chart plotters, eyeball navigation has largely been forgotten, and in some cases, the result has been disastrous. One can argue endlessly over paper versus e-charts, but one thing’s certain: Over-reliance on electronic navigation supports the local salvagers. Note the case of a Swan 90 hard aground on the western side of Antigua’s Spithead Channel. The grounding occurred because the skipper was looking at his chart plotter rather than using eyeball navigation. The salvage and repair costs ended up in the $800,000 ballpark. If you use common sense — not heading west to enter harbors after 1500 or heading east in reef-encumbered areas before 1100 — you can cruise the Caribbean relying completely on eyeball navigation, as is proved by two stories, one from the late 1950s, the other from the early 1960s.

Marv Berning and Bill Bailey, both in their very early 20s, were crewing on Le Voyageur (now Mariette) , a 131-foot Herreshoff schooner. They saved their money, left the boat and bought a 20-foot Bequia double-ender. They installed a deck with a big hatch so they had sleeping accommodations out of the spray and rain, then took off, spending two months cruising from Bequia to St. Thomas, in the U.S. Virgin Islands .

Their navigational equipment consisted of an Esso road map that showed all the islands and a dry Boy Scout compass. To keep the compass level so it would work, they glued it to a piece of wood that they floated in a half-filled gourd whose top had been cut off. They chocked the gourd so it did not fall over; the compass needle gave them north, and they estimated the other compass points. (Note: This was in the days when all sailors had to learn to box the compass, reading off the 32 points and the quarter points!)

In the early ’60s, my yawl Iolaire departed Grenada on a one-month sail to St. Thomas. The trip was a charter, and on board was a group of six young doctors doing their medical residency at Bellevue Hospital in New York. As we reached the northwest corner of Grenada, I discovered that, because of crossed wires, our charts of the Grenadines had been left in the Grenada Yacht Club bar. Neither I, nor my 18-year-old crewmember, Ed Pionkowski, had ever sailed the Grenadines. The only guide available was my Norie and Wilson Sailing Directions for the West Indies, published in 1867. It was an excellent guide, but for the Grenadines it gave no information other than that one should hire a local pilot.

I was not willing to go back to St. George’s to pick up the charts. Instead, I told Ed to take two small cockpit cushions to the lower spreaders and secure one on each so someone on either spreader would have a comfortable seat. We had a flag halyard on the starboard spreader and rigged another on the port spreader so that no matter which tack we were on, the person on the spreader could be supplied with cold Heineken.

In my early days of chartering and exploring the eastern Caribbean, often without the aid of a detailed chart, one of my crew or I would spend a lot of time conning Iolaire from a perch up the mast.

We spent a week cruising the Grenadines and later entered the Tobago Cays from the southern entrance, a pass that today the bareboat charter managers and guide authors claim is too difficult to use. We found that if there is good light and the skipper reads carefully the sailing instructions on the back of Imray Iolaire chart B31 or B311, or the piloting directions found in Street’s Cruising Guide to the Eastern Caribbean: Martinique to Trinidad, and uses eyeball navigation with a crewmember on the foredeck or up the mast, the southern entrance is not that difficult. Eyeball navigation is much better from the bow than from the cockpit, and standing on top of the bow pulpit is better still than standing on deck. If it is a tight situation or the light is fading, a crewmember piloting from the lower spreaders makes everything clear. In my early days of chartering and exploring the eastern Caribbean, often without the aid of a detailed chart, one of my crew or I would spend a lot of time conning Iolaire from a perch up the mast. Before the late 1970s, when Imray Iolaire charts became available in the marine hardware stores throughout the eastern Caribbean, obtaining charts in the islands was extremely difficult. We ordered ours from the United States or England, and it often took six weeks for them to arrive.

When I first bought Iolaire in 1957, she had a wooden mast with external halyards, thus it was no problem to climb aloft. But over time, rig problems eventually got to me. In 1962 we lost the mast in Anegada Passage. To salvage it, we towed the spar in to Norman Island — at that time, Iolaire had a very small engine that sometimes ran — and hoisted it on deck; powered back to St. Thomas; shortened and scarfed the spar; and were out on charter 11 days later.

Then, in 1966, we lost the top 10 feet of the mast off Dominica. The engine did not run, so we came up with a jury rig and sailed back to Grenada. We averaged 5.5 knots with me, daughter Dory, 7, and a young Grenadian crew aboard.

I decided finally I’d had enough of wooden spars that had to be regularly varnished and whose glue joints let go with disastrous consequences, so I installed an aluminum mast. Even so, I maintained the external halyards, and until I reached my mid-70s, I could still climb Iolaire’s mast without the aid of a bosun’s chair.

As my red beard started going gray and sailors began to ask how old I was, I would reply, “As long as my wife looks young enough to be my daughter and I can climb to the spreaders without the aid of a bosun’s chair, I am 38 and holding!” However, when we moved Iolaire to Europe and I started sailing about the Caribbean aboard Lil’ Iolaire, a 28-foot yawl that had an aluminum mast with internal halyards, I learned that climbing such a spar is only for the young and very fit. Once I realized it was almost impossible for me to climb to the spreaders, I immediately installed mast steps. Despite being over 70, I regularly went up the rig when entering harbors and exploring. In fact, the view from the lower spreaders is great!

Given that nearly all boats now have internal halyards, anyone headed for the Caribbean should check the various catalogs, find steps that are appealing and install them at least to the lower spreaders. Rigging steps is a job that can be done by ship’s crew with the mast in the boat.

Whenever there is a tricky pilotage situation, if someone is on the lower spreaders, everything becomes crystal clear. Also, at anchor, crew who are too nervous to go aloft under sail can climb the mast via the steps and obtain wonderful views and photographs that are not visible from deck level.

- More: coral , How To , mast , navigation

- More How To

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Rigging Redo: Our Switch to Synthetic

Top Tools for Sailboat Cruising: Must-Have Gear for 2024

Galápagos: A Paradise Worth the Paperwork

Around Alone

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

| (001) 401-739-1140 -- (001) 401-739-1149 | |

| |

| or Mast Feet, are used on Deck or Keel to secure the base of the Mast. Mast Steps are usually bolted through the Deck, or into the Keel. Some Deck Steps incorporate a means of attaching and other Control lines. Some Keel Steps incorporate a means of attaching various or Deck Tie-down attaching to the Deck or Deck Collar, to prevent Deck rise due to Rig Tension. , , , and the unrelated, but oft-confused, , for climbing. Rig-Rite stocks a wide selection of originally supplied by a variety of Manufacturers, as noted below, and is able to supply any type of , as required. are listed by specific Mast Section, See . , for Sections are shown listed here, please forward details on your See: . We will also need measurements, and full details of the part, boat model and year. If an original Step is not available, we are able to supply any type of , as noted below. are available separately, See: . to attach to standard Bails are available, See: . |

| Mast Steps for Sections on-site are shown below. | ||

| | ||

| Cast Aluminum Mast Step for use with Annapolis Spars 7446 Mast Section. Oval Mast Section is 7 3/8" x 4 9/16", Mast Step is 7 3/8" long x 4 5/8" wide with NO holes for attachment. Unit is marked

| ||

| Cast Aluminum Mast Step for use with Annapolis Spars 8553 Mast Section. Oval Mast Section is 8 1/2" x 5 1/4", Mast Step is 8 1/2" long x 5 1/4" wide with NO holes for attachment. Unit is marked

| ||

| | ||

| Cast Aluminum Mast Step for use with Columbia Yachts 6" x 4" Oval Mast Section. Anodized, Oval Deck-mounted Mast Step is 6 1/4" long x 4 1/4" wide and attaches to deck with (4) 1/4" screws on 2 1/2" x 1 1/2" centers. Unit features drainage slots, 2" x 1" center slot, and is marked

| ||

| Cast Aluminum Mast Step for use with Columbia Yachts 7 1/4" x 4 1/2" Oval Mast Section. Anodized, Oval Deck-mounted Mast Step is 7 7/16" long x 4 9/16" wide and attaches to deck with (4) 1/4" screws on 3" x 2" centers. Unit features drainage slots and 1" center hole.

| ||

| Cast Aluminum Mast Step for use with Columbia Yachts 7 1/4" x 4 1/2" Oval Mast Section. Anodized, Rectangular Keel-mounted Mast Step is 8 1/2" long x 6 7/8" wide and attaches to Keel with (2) 1/2" bolts, and (2) 5/16" screws in 2 1/4" long slots. Unit features drainage slots, 2 1/4" x 1 1/2" center slot, and is marked and others.

| ||

| Cast Aluminum Mast Step for use with Columbia Yachts 8 1/2" x 5 3/4" Oval Mast Section. Anodized, Rectangular Mast Step is 11" long x 6 7/8" wide and attaches to Keel with (4) 1/4" bolts in 1" long slots. Unit is marked

| ||

| Aluminum Mast Step for use with Columbia Yachts Mast Section. Rectangular Keel-mounted Mast Step is 9 3/8" long x 6" wide and attaches to Keel with (4) 1/2" bolts in 1 3/4" long slots. Welded Mast Step has Black epoxy coating. and others.

| ||

| | ||

| Cast Aluminum Mast Step for Famet 4530 (4 1/2" x 3") Flat Oval Mast Section. Mast Step measures 4 1/2" long x 3" wide x 1 1/4" high, with NO holes for attachment. Cast in 356 Aluminum with anodized finish. and others.

| ||

| Hinged tabernacle assembly for Famet 4530 section allows for easy mast-stepping. Consists of Mast Step casting bolted to . When replacing the original 2-piece Tabernacle used on Balboa, Ensenada 20, and others, a 1/2" Spacer, , (below) is required to maintain original Mast height.

| ||

| Spacer Plate or Riser for Hinged Mast Plate Assembly is 1/2" thick, and fits Bottom Hinge plate to increase Mast height by 1/2" or multiples of 1/2". Useful where mast needs to be cut, or as an easy way to solve rigging stretch problems. High-density Plastic Spacer Plate is 6 1/2" long x 3 3/4" wide x 1/2" thick, and is drilled to match the Bottom Plate ( ).

| ||

| Cast Aluminum Mast Step for Famet 5032, L-106 (5" x 3 1/4") Flat Oval Mast Section. Mast Step is 5" long x 3 1/2" wide x 1 1/4" high, with NO holes for attachment. Cast in 356 Aluminum with anodized finish.

| ||

| Hinged tabernacle assembly for Famet 5032 section allows for easy mast-stepping. Consists of Mast Step casting bolted to

| ||

| Cast Aluminum Mast Step for Famet 6535 (6 1/2" x 3 1/2") Flat Oval Mast Section. Mast Step measures 6 5/8" long x 3 5/8" wide x 1 1/4" high, with NO holes for attachment. Cast in 356 Aluminum with anodized finish.

| ||

| | ||

| Mast Step for Forespar 6210 Mast Section (10" x 6 1/4") fastens to deck, keel or keelson with (4) 3/8" bolts in internal adjustment slots to allow for precise positioning. Mast Step is 10 1/2" long x 6 7/8" wide, slots allow for 1" fore and aft adjustment. Slot centers are 2 1/4" athwartships, and 4" fore & aft, unit has 1 1/4" Center hole. Part is marked and Cast in 356 Aluminum with anodized finish.

| ||

| | ||

| Mast Step Assembly for Hall Spars 095 Mast Section (3.75 x 2.75) fastens to various SS plates w/ (4) 3/8" bolts. New-style Assembly includes sheaves with removable Axles and Cover Plates, and SS Vang Bail. Mast Step Base is 6 1/2" long x 4" wide, Casting is marked Cast in 356 Aluminum with anodized finish.

| ||

| New-style Mast Step Casting Only has tapped holes for Sheave Cover Plates (w/ new removable Axles), and hole for SS Vang Bail. Mast Step Casting Only for Hall Spars 095 Mast Section (3.75 x 2.75) fastens to various SS plates w/ (4) 3/8" bolts. Cast in 356 Aluminum with anodized finish.

| ||

| Mast Step for Hall Spars 128 Mast Section (5" x 3.2") fastens to keel or keelson w/ (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unsteping the mast. Mast Step measures 9" long x 3 1/2" wide, slots allow for 1" fore & aft adjustment. Slot centers are 1 5/8" athwartships, & 7" fore & aft. Part is marked Cast in 356 Aluminum with anodized finish. & others.

| ||

| Mast Step for Hall Spars 152 Mast Section (6" x 4") fastens to keel or keelson with (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step measures 9 3/8" long x 4 3/8" wide, slots allow for 1 1/2" fore and aft adjustment. Slot centers are 3 3/8" athwartships, and 7" fore & aft, unit has 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish. and others.

| ||

| Special Base Plate for Mumm 30 attaches to keel and receives Plug attached to Carbon Mast. Extruded Aluminum Channel Plate attaches to keelson with (4) 5/16" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Hardcoat anodized unit is 9 3/4" long x 3" wide, slots allow for 1" fore and aft adjustment. Slot centers are 1 3/4" athwartships, and 7 3/4" fore & aft, unit includes (2) 3/8" SS bolts to secure Mast.

| ||

| Mast Step for Hall Spars 166 Mast Section (6.50" x 4") fastens to keel or keelson with (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step measures 7 1/2" long x 6" wide, slots allow for 2" fore and aft adjustment. Slot centers are 5" athwartships, and 4 1/2" fore & aft. Part is marked Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Schaefer Spars 180 Mast Section (7 1/8" x 4 1/2") fastens to deck with (4) 1/4" bolts in adjustment slots to allow for precise positioning. Mast Step is (maximum) 7 7/8" long x 5 1/4" wide, slots allow for 1" fore and aft adjustment. Slot centers are 2" athwartships, and 3" fore & aft, unit has 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Schaefer Spars 180 Mast Section (7 1/8" x 4 1/2") fastens to keel or keelson with (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step measures 9 1/2" long x 5 5/8" wide, slots allow for 1" fore and aft adjustment. Slot centers are 4 5/16" athwartships, and 7 1/4" fore & aft, unit has 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish.

| ||

| Mast Step for Schaefer Spars 200 Mast Section (7.685" x 4.86") fastens to deck with (4) 3/8" bolts in adjustment slots to allow for precise positioning. Mast Step is (maximum) 8 1/2" long x 5 9/16" wide, slots allow for 1" fore and aft adjustment. Slot centers are 1 3/4" (fwd.) and 2" (aft) athwartships, and 3" fore & aft, unit has 1 1/2" Center hole. Part is marked and Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Schaefer Spars 200 Mast Section (7.685" x 4.86") fastens to keel or keelson with (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step measures 10" long x 7 1/4" wide, slots allow for 1" fore and aft adjustment. Slot centers are 6" athwartships, and 7 3/4" fore & aft, unit has 1 1/2" Center hole. Part is marked and Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Schaefer Spars 205 Mast Section (8.06" x 4.88") fastens to deck or keel with (4) 3/8" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step is (maximum) 10 1/2" long x 6" wide, slots allow for 2" fore and aft adjustment. Slot centers are 4 7/8" athwartships, and 7 1/2" fore & aft. With 1 1/2" x 3" Center slot. Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Schaefer Spars 220 Mast Section (8.55" x 5.40") fastens to deck or keel with (4) 3/8" bolts in adjustment slots to allow for precise positioning. Mast Step is (maximum) 9 3/8" long x 5 15/16" wide, slots allow for 1" fore and aft adjustment. Slot centers are 2 1/2" athwartships, and 4 1/8" fore & aft. With 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish. MMM SLC

| ||

| Mast Step for Schaefer Spars 230 Mast Section (9.233" x 5.82") fastens to deck or keel with (4) 1/2" bolts in adjustment slots to allow for precise positioning. Mast Step is (maximum) 10" long x 6 5/8" wide, slots allow for 1" fore and aft adjustment. Slot centers are 2 1/4" athwartships, and 4 1/4" fore & aft. With 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish.

| ||

| Mast Step for Schaefer Spars 240 Mast Section (9.91" x 6.20") fastens to deck or keel with (4) 1/2" bolts in adjustment slots to allow for precise positioning. Mast Step is (maximum) 10 5/8" long x 7 1/16" wide, slots allow for 1" fore and aft adjustment. Slot centers are 2 3/4" athwartships, and 4 3/4" fore & aft. With 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish.

| ||

| Mast Step for Schaefer Spars 240 Mast Section (9.91" x 6.20") fastens to keel or keelson with (4) 1/2" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step is (maximum) 13" long x 9" wide, slots allow for 1 1/2" fore and aft adjustment. Slot centers are 7 1/2" athwartships, and 10" fore & aft. With 1 1/2" Center hole. Cast in 356 Aluminum with anodized finish. and others.

| ||

| Mast Step for Hall Spars 9641 and 9642 Mast Sections fastens to keel or keelson with (4) 1/2" bolts in external adjustment slots to allow for precise positioning without unstepping the mast. Mast Step is 12 1/2" long x 7" wide, slots allow for 2" fore and aft adjustment. Slot centers are 5 1/2" athwartships, and 9" fore & aft. Part is marked Cast in 356 Aluminum with anodized finish.

| ||

| | ||

| Mast Step for Hood Stoway 9555 Section (9 1/2" x 5 1/2"). Cast Aluminum Mast Step is (maximum) 10 1/2" long x 6 1/2" wide x 1 3/4" high with 1 1/4" ID Electrical stand pipe and Black anodized finish. Marked 6271-004.

| ||

| Mast Step for Hood Stoway 1267 Section (12.3" x 6.75"). Cast Aluminum Mast Step is (maximum) 14 1/2" long x 11 7/8" wide x 2 1/2" high with 1 1/2" ID Electrical stand pipe hole (3 1/2" high) and anodized finish. Unit mounts with 1/2" bolts in (4) 9/16" x 3" slots on 10 1/4" athwartships centers x 8 1/2" fore & aft centers. Marked HYS 6161 04.

| ||

| | ||

| Mast Step for MetalMast 6035 Teardrop Mast Section (6" x 3 1/2") has (2) Tenons (1 1/8" square x 1 1/8" deep) to fit in special deck receiver. Cast Aluminum Mast Step is (maximum) 6" long x 3 1/2" wide with clear anodized finish. and others.

| ||

| for MetalMast 6641 Oval Section: MM 6641M-S1: | ||

| Mast Step for MetalMast 6641 Oval Mast Section (6.62" x 4.12") is undrilled to adapt to any mounting hole configuration. Cast Aluminum Mast Step is (maximum) 6 1/4" long x 4 1/8" wide with Light Gray Awlgrip finish. and others.

| ||

| for MetalMast 6641 Oval Section: MM 6641M-S2: | ||

| Mast Step for MetalMast 6641 Oval Mast Section (6.62" x 4.12") fastens to keel or deck with (2) 3/8" bolts on 3 1/2" centers. Welded Aluminum Mast Step is (maximum) 8 1/4" long x 5 5/8" wide with clear anodized finish. Replaces earlier Cast version.

| ||

| Mast Step for MetalMast 6641 Oval Mast Section (6.62" x 4.12") fastens to deck with (2) 5/16" bolts on 3 7/8" centers. Cast Aluminum Mast Step is (maximum) 7" long x 4 1/2" wide with clear anodized finish. Unit is marked and others. Fits MM 6641 Mast Section, and other variations of this section.

| ||

| Mast Step for MetalMast 7041 Teardrop Mast Section (7" x 4.11") fastens to keel or keelson with (2) 3/8" bolts on 8 1/4" centers. Mast Step is (maximum) 10" long x 4 3/8" wide. Cast in 356 Aluminum, fully machined with a clear anodized finish. and others.

| ||

| Mast Step for MetalMast 7244 Oval Mast Section (7.31" x 4 1/2") fastens to keel or keelson with (2) 3/8" bolts on 8 3/4" centers. Mast Step is (maximum) 10 1/2" long x 4 3/4" wide. Cast in 356 Aluminum, fully machined with a clear anodized finish. Unit is marked Can be modified for use as Deck Step, as on and others.

| ||

| Mast Step for MetalMast 7244 Oval Mast Section (7.31" x 4 1/2") with Custom 4" Riser fastens to keel or keelson with (2) 3/8" bolts on 8 3/4" centers. Custom Riser is welded from 6061-T6 Aluminum Plate with a clear anodized finish and is designed to fit footprint of Mast Step. Shown at 4" high, but Riser can be made in any height to allow for trimming of corroded Mast bottom.

| ||

| Mast Step for MetalMast 7845 (-1 & -2) Teardrop Mast Sections (7.8" x 4.51") fastens to keel or deck with (2) 3/8" bolts on 3 1/4" centers. Welded Aluminum Mast Step is (maximum) 8 3/8" long x 5 5/8" wide with clear anodized finish. Replaces earlier Cast version.

| ||

| Domed Mast Step Plug for MetalMast 7845-1 Mast Section (7.8" x 4.51") fastens to mast with (4) 1/4" screws. Anodized, cast Aluminum Mast Plug is (maximum) 8" long x 4 5/8" wide, with 1" center hole. As used on a variety of Bristol and Pearson Yachts.

| ||

| Domed Mast Step Plug for MetalMast 7845-2 Mast Section (7.8" x 4.51") fastens to mast with (4) 1/4" screws. Anodized, cast Aluminum Mast Plug is (maximum) 8" long x 4 5/8" wide, with 1" center hole. As used on a variety of Bristol and Pearson Yachts.

| ||

| Oval Deck Step receiver for Domed Mast Step Plug is (maximum) 9 5/8" long x 6" wide x 2" high, with 1" center hole. Anodized casting has no fastener holes but was originally attached with (6 or 8) 1/4" FH screws in various patterns. As used on a variety of Bristol Yachts and and others.

| ||

| Mast Step for MetalMast 8348 Teardrop Mast Section (8.3" x 4.81") fastens to keel or deck and is undrilled to adapt to any mounting hole configuration. Cast Aluminum Mast Step is (maximum) 9 3/16" long x 5 13/16" wide with unfinished surface.

| ||

| Aluminum Keel-mount Mast Step for Mast replaces Steel original, as used on (some) 's. Anodized aluminum Mast Step is 15" long x 6 1/2" wide, with (4) 7/8" x 2 1/2" slots on 3 5/8" centers and 7/16" bridged hole for deck tie down rod. As original Steel Steps varied widely, mounting may require new holes. Similar to as pictured here. and others.

| ||

| Mast Step for MetalMast 8655 Oval Mast Section (8.6" x 5.5") fastens to keel or deck with (4) 1/4" screws on 7 1/2" x 4 3/4" centers. Cast Aluminum Mast Step is (maximum) 9 1/2" long x 6 3/4" wide with clear anodized finish.

| ||

| | ||

| Cast Aluminum Mast Step for use with Sound Spar 7747 Mast Section. Oval Mast Section is 7 3/4" x 4 3/4", Mast Step is 7 3/4" long x 4 3/4" wide and attaches to deck or keel with (2) 3/8" bolts in 1 1/2" long slots on 4" centers. and others.

| ||

| Aluminum Keel-mount Mast Step for Sound Spar Mast (7 3/4" x 4 3/4") replaces Steel original, as used on (some) 's. Anodized aluminum Mast Step is 15" long x 6 1/2" wide, with (4) 1/2" x 2 3/8" slots on 4 1/2" centers and 7/16" bridged hole for deck tie down rod. As original Steel Steps varied widely, mounting may require new holes. Similar to as pictured here. and others.

| ||

| Cast Aluminum Mast Step for use with Sound Spar 8755 Mast Section. Oval Mast Section is 8 3/4" x 5 1/2", Mast Step is 11 1/4" long x 7 1/8" wide and attaches to keel with (4) 1/4" bolts in 3 1/4" long slots on 6", and 3 1/4" centers. Unit features drainage slots, 4" x 1 1/2" center slot, and is marked ****

| ||

| Aluminum Keel-mount Mast Step for Sound Spar Mast (8 3/4" x 5 1/2") replaces Steel original, as used on (some) 's. Anodized aluminum Mast Step is 15" long x 6 1/2" wide, with (4) 1/2" x 2 3/8" slots on 4 1/2" centers and 7/16" bridged hole for deck tie down rod. As original Steel Steps varied widely, mounting may require new holes. and others.

| ||

| | ||

| Cast Aluminum Mast Step for use with Sparcraft (California) Mast Section. S-108 Flat-sided Oval Mast Section is (maximum) 4 1/2" long x 3" wide. and others.

| ||

| Cast Aluminum Mast Step for use with Sparcraft (California) Mast Section. S-107 Teardrop-shaped Mast Section is (maximum) 5 5/8" long x 4" wide. and others.

| ||

| Custom Mast Steps are available in any number of varieties and materials. Common arrangements are detailed below, or specify any other configuration. We now commonly make Custom Aluminum Keel-mounted Mast Steps, with an integral Riser (of varying heights). For older Rigs with corrosion problems, this allows the removal of the bottom several inches of Mast Section without affecting Rig height.

| ||

| Simple Custom Aluminum Deck-mount Mast Step. For Quotation, Specify Mast Section, fastener size and spacing, and other requirements.

| ||

| Custom Aluminum Keel-mount Mast Step. For Quotation, Specify Mast Section, and other requirements. Design is similar to , as pictured here and and others.

| ||

| Custom Aluminum Keel-mount Mast Step with Riser. For Quotation, Specify Mast Section, and other requirements. Commonly used on replacements for original Pearson Steel Mast Steps, where corrosion forces removal of several inches of Mast Section. Design is similar to custom Mast Step as pictured here.

| ||

| Mast Step Base Plate Adapters are used to adapt a standard Mast Step for use in an externally adjustable Keel-stepped application. Standard items are detailed below, any others are available on a Custom basis, please supply details.

| |

| Mast Step Base Plate Adapter converts standard mast step for use with external adjustment screws, on keel-stepped rigs. Fastens with (2) 5/16" FH screws in standard holes of E, 2740, 3049, 3350, 3550, 3656, and other Kenyon mast steps. Allows for precise positioning without unstepping the mast. Anodized aluminum plate is and measures Fastens to keelson with (4) 3/8" bolts in Slots that allow for 1 1/2" adjustment. Slot centers are 3 5/8" athwartships, and 5 3/4" fore & aft. and others.

|

|

| Mast Step Base Plate Adapter converts standard mast step for use with external adjustment screws, on keel-stepped rigs. Fastens with (4) 3/8" FH screws in internal adjustment slots of 4066 mast step, Allows for precise positioning without un-stepping the mast. Anodized aluminum plate is and measures Fastens to keelson with (4) 3/8" bolts in Slots that allow for 1 1/8" adjustment. Slot centers are 4 1/4" athwartships, and 7" fore & aft. and others.

| |

| Mast Step Base Plate Adapter converts standard mast step for use with external adjustment screws, on keel-stepped rigs. Fastens with (4) 3/8" FH screws in internal adjustment slots of 4270, and 4477 mast steps. Allows for precise positioning without un-stepping the mast. Anodized aluminum plate is and measures Fastens to keelson with (4) 3/8" bolts in Slots that allow for 1 1/4" adjustment. Slot centers are 4 3/4" athwartships, and 8 1/8" fore & aft. and and others, and on and others.

|

|

| Mast Step Base Plate Adapter converts standard mast step for use with external adjustment screws, on keel-stepped rigs. Fastens with (4) 3/8" FH screws in internal adjustment slots of 4873 mast step, Allows for precise positioning without un-stepping the mast. Anodized aluminum plate is and measures Fastens to keelson with (4) 3/8" bolts in Slots that allow for 2" adjustment. Slot centers are 5 1/2" athwartships, and 7 1/2" fore & aft. and others, and on and others. | |

~ Back to Spars Main Page ~

- Maint & DIY

- Nav & Electronics

Table of Contents

Understanding Mast Steps

Mast steps are small platforms or rungs that are attached to the mast of a sailboat to allow sailors to climb up and down safely. These steps are essential for accessing the sails, rigging , and other parts of the sailboat that are located high above the deck. Whether you need to perform maintenance, make repairs, or simply enjoy the views from the top of the mast, mast steps are a crucial piece of equipment for any sailor.

The Importance of Secure Mast Steps

Having secure and durable mast steps is essential for ensuring the safety of anyone climbing the mast. Loose or damaged steps can lead to accidents and injuries, so it is crucial to regularly inspect and maintain the steps on your sailboat. Look for signs of wear and tear, such as rust, corrosion, or cracks, and replace any damaged steps immediately to prevent accidents.

This image is property of pixabay.com.

Types of Mast Steps

There are several types of mast steps available on the market, each with its own unique features and benefits. It is essential to choose the right type of mast steps for your sailboat based on your specific needs and preferences.

Folding Mast Steps

Folding mast steps are a popular choice among sailors due to their versatility and convenience. These steps can be folded flat against the mast when not in use, making them ideal for sailboats with limited space or for sailors who prefer a more streamlined look. Folding mast steps are easy to install and remove, making them a practical option for temporary use.

Fixed Mast Steps

Fixed mast steps are permanently attached to the mast and cannot be folded or removed. These steps are typically more robust and durable than folding steps, making them an excellent choice for sailors who need a reliable climbing solution. Fixed mast steps provide a stable and secure platform for climbing, making them ideal for long-distance sailing or rough conditions.

Removable Mast Steps

Removable mast steps are a flexible option that can be easily installed and removed as needed. These steps are ideal for sailors who prefer to keep their mast clutter-free when not in use. Removable mast steps are lightweight and easy to store, making them a convenient choice for occasional climbers.

Installing Mast Steps

Installing mast steps on your sailboat is a straightforward process that can be completed with basic tools and materials. Whether you choose folding, fixed, or removable steps, the installation process is relatively similar for all types of mast steps.

Tools and Materials Needed

Before installing mast steps on your sailboat, gather the following tools and materials:

- Drill and drill bits

- Screwdriver

- Stainless steel screws

- Mast step kit (includes steps and mounting hardware)

- Ladder or scaffolding (for reaching the mast)

Step-by-Step Installation

- Prepare the Mast: Before installing mast steps, clean the area where the steps will be mounted to ensure a secure attachment. Remove any dirt, debris, or old hardware from the mast to create a clean surface for the steps.

- Position the Steps: Determine the desired placement of the mast steps on the mast based on your climbing preferences and the layout of the sailboat. Ensure that the steps are evenly spaced and aligned vertically for safe climbing.

- Drill Holes: Use a drill and drill bits to create pilot holes in the mast where the mounting screws will be installed. Be sure to drill straight and evenly spaced holes to ensure a secure attachment for the steps.

- Install the Steps: Secure the mast steps to the mast using stainless steel screws and the provided mounting hardware. Tighten the screws firmly to prevent the steps from shifting or coming loose during climbing. Repeat this process for each step until all steps are securely mounted on the mast.

- Test the Steps: Once the mast steps are installed, give them a thorough test to ensure that they are secure and stable. Climb up and down the mast carefully to check for any movement or instability in the steps. Make any necessary adjustments to the mounting hardware to ensure a safe climbing experience.

Safety Tips for Climbing the Mast

Climbing the mast of a sailboat can be a challenging and potentially dangerous task, so it is essential to follow safety guidelines to prevent accidents and injuries. Here are some safety tips to keep in mind when climbing the mast:

- Always wear a harness and safety line when climbing the mast to prevent falls.

- Use a climbing buddy or spotter to assist you when climbing the mast.

- Check the weather conditions before climbing the mast and avoid climbing in high winds or rough seas.

- Inspect the mast steps and rigging before climbing to ensure that everything is in good condition.

- Take your time and climb carefully, paying attention to your footing and handholds.

Maintaining Mast Steps

Proper maintenance of mast steps is essential for ensuring their long-term durability and safety. Regular inspection and cleaning can help prevent corrosion, rust, and other issues that can compromise the integrity of the steps.

Cleaning Mast Steps

To clean mast steps, use a mild soap and water solution to remove dirt, salt, and grime from the steps. Avoid using harsh chemicals or abrasive cleaners that may damage the steps or the mast. Rinse the steps thoroughly with clean water after cleaning to remove any residue.

Inspecting Mast Steps

Regularly inspect mast steps for signs of wear and tear, including rust, corrosion, cracks, or loose mounting hardware. Replace any damaged steps or hardware immediately to prevent accidents and injuries. Check the steps before each climb to ensure that they are secure and stable.

Lubricating Mast Steps

To prevent corrosion and ensure smooth operation, lubricate the hinges and moving parts of folding mast steps regularly. Use a marine-grade lubricant to protect the steps from saltwater corrosion and to maintain their functionality over time. Lubricate the steps according to the manufacturer’s recommendations to keep them operating smoothly.

Climbing the mast of a sailboat can be a thrilling experience that offers breathtaking views and a unique perspective on the water. With the right mast steps and proper safety precautions, you can safely navigate the heights of a sailboat and enjoy all the advantages that come with it. Whether you are a seasoned sailor or a novice adventurer, mast steps are an essential tool for exploring the world of sailing from a whole new vantage point. Happy sailing!

You Might Also Like

Nautical Knot Tying Kit Review

Trimming the Mainsail

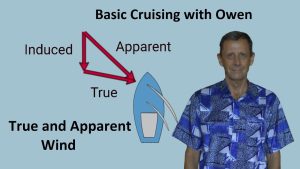

Comprehensive Overview: True Wind vs. Apparent Wind

Sail Whisperer is a website designed to help you make a more informed decision when buying sail components.

Connect with us.

Accessories Cloths Safety

- Maintenance & DIY

- Navigation & Electronics

- News & Updates

- Policy Privacy

- Affiliate Disclosure

- Terms of Use

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine .

Check out our latest sailing content:

Stepping and unstepping a mast.

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations.

I am ready to help you with booking a boat for your dream vacation. Contact me.

Denisa Kliner Nguyenová

Euro Marine Trading

- Whisper Power

FOLDING MAST STEPS for EASIER & SAFER SAIL STOWING! or climbing the mast

How many yachtsmen have struggled to reach the gooseneck, the highest reef point or the top of he sail cover by attempting to balance on a halyard, winch or something even smaller? Well now there’s a quick and simple solution for this risky and dangerous activity.

Now available are the new “lightweight, rattle free, aesthetic, strong and foldable” mast steps. These steps are easily unobtrusively fitted to the mast providing safe and secure footholds while climbing or working the mast.

The folding mast step is manufactured from a special combination of Nylon/Glass fiber which together with its design gives the step enormous strength. With a 3% additive, it makes the mast step UV resistant and prevents material degradation.

The steps weighs only 165grams each (weight is always a consideration for products up a mast), and when folded does not snag ropes or sails due to the ‘snag-free’ design. At anchor or on a mooring the steps do not rattle in the wind and there is a choice of colors to match the mast – white, black and grey.

The steps are placed on opposite sides of the mast with a recommended spacing of 375mm and two opposite each other 1200mm down from the top of the mast for stable and safe working on sheaves, halyards and masthead instruments. Due to its construction and the materials used, it is easy to adjust the step to fit the radius of the mast. Simply tape a sheet of sand paper at the position where the step is to be fitted, rub the saddle of the step up and down until the step snugly fit’s the mast curvature.

When using the steps to climb the mast, one simply unfolds the steps in front as one ascends and folds them behind him as you descend the mast. The steps also provide a secure foothold but it is always strongly recommended to use a harness with a safety line attached.

There are many benefits of using the reinforced Nylon/Glass fiber folding mast steps, here are a few of them:

- Lightweight

- Corrosion free

- No electrolysis as with stainless steel fitted to aluminum

- No rattling

- Available in Grey, Black and White

- UV resistant

MAST MATE CLIMBING SYSTEM

The original mast ladder, made in the USA since 1989.

A Skipper’s First Mate Is Self Reliance Sailboat ladder or mast ladder that allows one to climb the mast alone for maintenance.

CLIMBING SYSTEM

Mast Mate is an alternating-step, flexible mast ladder made of 2 inch-wide nylon webbing. Each mast step is reinforced with an additional piece of webbing.The sewn tensile strength of the webbing is a minimum of 3,000 pounds.

TOOL BAG WORKBELT

The design is similar to a linesman’s belt, consisting of an adjustable waist belt with a tool bag conveniently affixed at the back and a tether strap that goes around the mast and clips back onto the opposite side of the belt…

DEAR SAILOR

Thank you for your

interest in the Mast

Mate Climbing

System…

I take pride in introducing you to Mast Mate, an efficient, single-handed, patented mast climbing device and the practical Tool Bag Workbelt. Combined, they make going aloft and working a simple, easy and, most importantly, safe experience. As a sailor, I know that going aloft is a serious matter, be it at the dock or underway. The quality of Mast Mate and the Workbelt reflect that belief.

All our mast step ladders and Tool Bag Workbelts are made in the U.S.A with quality materials and meticulous craftmanship. Whether you cruise, day sail or race, mast maintenance is a chore that cannot be overlooked. If it is, you will pay the price in time and money, or worse! Mast Mate can be rigged in five minutes and climbed in less time than that. Combined with the Workbelt securing you to the mast, small repairs like changing a bulb or fixing a wind indicator, as well as larger jobs, such as replacing shrouds or varnishing can be attended to without assistance. No more winching; no more scouting the dock for help; no more not quite being able to reach the masthead.

Over the years, we have supplied the Mast Mate Climbing System to Single Handed Transpac Racers, as well as to a number of challengers in the Ostar Races. A single hander has no one but himself to count on. I am sure you will find the Mast Mate Climbing System the best method for climbing and working aloft.

TESTIMONIALS

Thank you to Nic Morgan from “The Boat Life Blogger” for this video. His blog is fun and informative.

Please do not use the work belt as a safety harness. Use the work belt around the mast when you are in position to work.

I went up the mast using MastMate today, in order to repair the wind speed indicator. Here are my takeaways:

Feel Free to Contact Us for More Info.

Phone Number

Be sure to add the numbers above and THEN SUBMIT! It keeps your data safe.

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

How to Step a Mast Single-Handed With or Without Using the Boom as a Gin Pole

How do you step the mast on your trailerable sailboat? With a gin pole? With the trailer winch? With the help of friends or family? With your fingers crossed? No single system works for every sailboat or for every skipper. If you’re new to mast stepping, you don’t like your current method, or you just want to simplify or speed up the process, this post is for you. I must warn you though, this is a long post, even for me. To make it as short as possible, I’ve included five YouTube videos that show how this system works. By the end of this post, you’ll know everything about how I step the mast on Summer Dance single-handed in minutes, even on the water.

I’ll describe two ways that I step the mast, including one way that doesn’t use a gin pole at all. Both are fast and mostly use the boat’s own rigging and very little extra gear.

I’ll also explain some topics that lead up to and follow mast stepping, like how I:

- Use a DIY telescoping mast crutch for easier stepping and secure trailering.

- Tie down the mast and rigging for trailering.

- Keep my mast in tune without having to loosen and re-tighten the shroud turnbuckles to step the mast.

What do you really need?

When I started trailering Summer Dance years ago, I researched a lot about mast stepping. The Catalina 22 Owner’s Manual and General Handbook is pretty brief on the subject.

Walk the mast aft and drop the mast foot into the mast step on top of the deck, keeping the mast in center line of boat, insert the pivot bolt and locking nut. One crew member should pull on a line tied securely to the forestay while another pushes up on the mast and walks from the cockpit forward. With the mast erect, attach the forestay and forward lower shrouds.

Poorly written but pretty simple, huh? One crew member pulls on the forestay while another pushes on the mast. That’s how the mast was designed to be stepped and it works well if you’re young, strong, and there are two or more of you to do the job.

But what if you don’t normally have a second able crew member? What if you need to step the mast on the water? What if you want to lower the mast to go under a bridge? What if you or your crew have a physical impairment that prevents them from performing one of the tasks? That system may not work for you and you need an alternative. If you believe in the rule that you should have a backup for every critical part and system, then you also need a backup mast stepping plan even if you normally step the mast with the factory recommended method.

I’ve read about lots of different systems. Maybe you have too:

- Factory-built gin poles, braces, guy wires, and mast-ups

- DIY wooden gin poles with winches, bridles, and brace poles

- Blocks attached to the pulpit to reuse the trailer winch cable

- Electric winches on the trailer or in the tow vehicle

- Jumbo bungee cord connected to the forestay

- Assorted Rube Goldberg variations on all the above

They all struck me as overkill for the real problem. What do you really need once you have the mast bolted to the step? What do all of these system have in common? Some mechanical advantage to raise the mast and a way to keep it from swinging too far sideways until the shrouds tighten.

If you’ve read this blog for very long at all, you know that I’m really big on reusing or repurposing things for other uses. It’s something of a prerequisite to be a stingy sailor. If you’re lucky, it’s in your DNA and it comes easily to you. Being an armchair engineer qualifies too.

Let’s see — sailboat design is all about capturing, multiplying, and redirecting forces for mechanical advantage: the hull, keel, rudder, mast, sails, rigging, almost everything. What’s the most compact, portable piece of gear on a sailboat that creates mechanical advantage? The main sheet or the boom vang typically multiplies the force applied to it by three or four times. What are all gin poles in their most basic form? A big stick. Is there already a long, stiff, portable, stick onboard? The boom. Can we raise and lower the mast single-handed with the main sheet and the boom?

As it turns out, it’s really pretty easy to do. But it’s not very easy to describe in words, so rather than write an entire book about it, I’ve made a series of short videos that each show a different aspect of my mast stepping system. I’ll give you an overview of each aspect in the text below but to really get it, you should watch the videos.

Getting it to the water

Besides being simpler, one of the basic principles of this system is to make launching and retrieving the boat as quick as possible while also being safe. That starts with securing the mast and rigging for trailering. For me, it has to be secure enough to tow for a hundred miles over bumpy state highways and county backroads to my favorite cruising spots. This is in north Idaho, mind you, which is relatively remote compared to the Florida coast or southern California.

I use a combination of DIY mast supports, motorcycle straps, and inexpensive ball cords to secure the rig. The mast is supported on both ends and in the middle. This follows closely the Catalina 22 Owner’s Manual and General Handbook recommendation.

Tie the mast and boom securely to the bow and stern pulpits. The spars should also be supported in the middle by the cabin top. Pad the mast at all contact points to prevent damage.

No tools or knot tying are needed for my system and any one of them works in seconds and stows easily either onboard or in my pickup.

Here’s a tour of the rig tied down just before I step the mast.

The previous video mentions my DIY mast stepper, also called a Mastup by a popular online Catalina parts retailer. I haven’t yet devoted a blog post to it but it was pretty easy to make. If you’re interested in a fabrication drawing and materials list, keep reading to the end of this post and a special offer.

I bought the steel myself from the cutoff pile at a local metal distributor. I took the metal and my drawing to a local welder who advertised on craigslist.com. I painted and assembled it myself. The total cost was half the price of the commercial version and in some ways, works even better. I especially like the D rings, which make it simple to secure the top of the mast stepper to the aft mooring cleats while trailering. It holds the mast very solid that way. And because the pintles are welded in place instead of adjustable, they can’t accidentally loosen and drop the mast.

Following is a close-up video of just the mast stepper. You can see it in action in the last two videos.

Setting up the boom as a gin pole

The basic theory of a gin pole is to lift a heavy object below one end while it remains stationary at the other end. Support lines called guys position the lifting end over the object that is raised. A mast raising gin pole has one end stationary near the base of the mast, uses the forestay to support the lifting end, and uses a winch or a block and tackle to theoretically raise the bow of the sailboat to the end of the gin pole. In reality, the bow stays stationary and the entire gin pole system including its base (the mast) are raised towards the bow.